Description

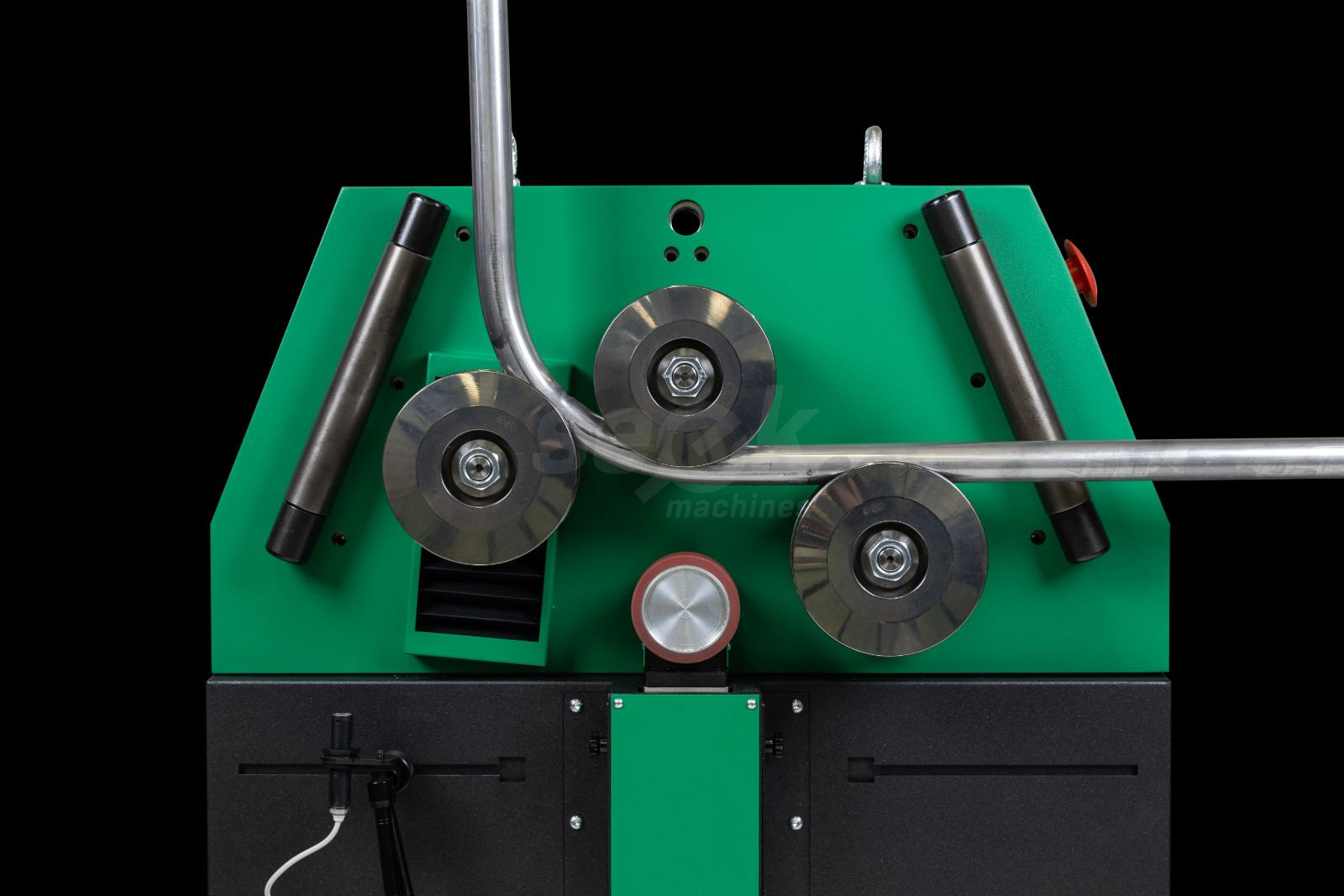

Computerized numerical control (CNC) bending machine operating in manual and automatic cycle, with direct insertion of the radius and bending data, to obtain many different shapes and developments

Electronic control consisting of a central 64-bit PLC system for controlling the movement of the A1 -A2 axes and a computer

LCD-VGA-HDMI-15 “color active matrix monitor, for the interface with the operator, both assembled on an independent console

Side ports for female USB and LAN RJ45 connections

Retractable control keyboard and control mouse

Multi language BPR bending program “PROBENDING ® system” facilitated with acquisition of the type of material and the section of the profile, possibility of filing the work performed with predefined and parameterized bending with memorization of the program combined with the selected material

Acquisition and transfer of DXF files

Execution of variable radius bends, with interpolated axes system

Ramps of acceleration and deceleration, stop and inversion of the cycle, self-learning program and mirror cycle

Progress reading encoder with pneumatic movement contact, cycle start limit switch, connection for digital archimeter

Electronic control of the speed settings of moving of the bending roll and of the profile displacement in manual or automatic cycle

Possibility of direct connection with an external personal computer via RJ-45 (LAN) with diagnostics and automatic setup of the machine. USB connection for transferring and copying of bending programs

Remote connection for remote assistance and preparation for INDUSTRY 4.0